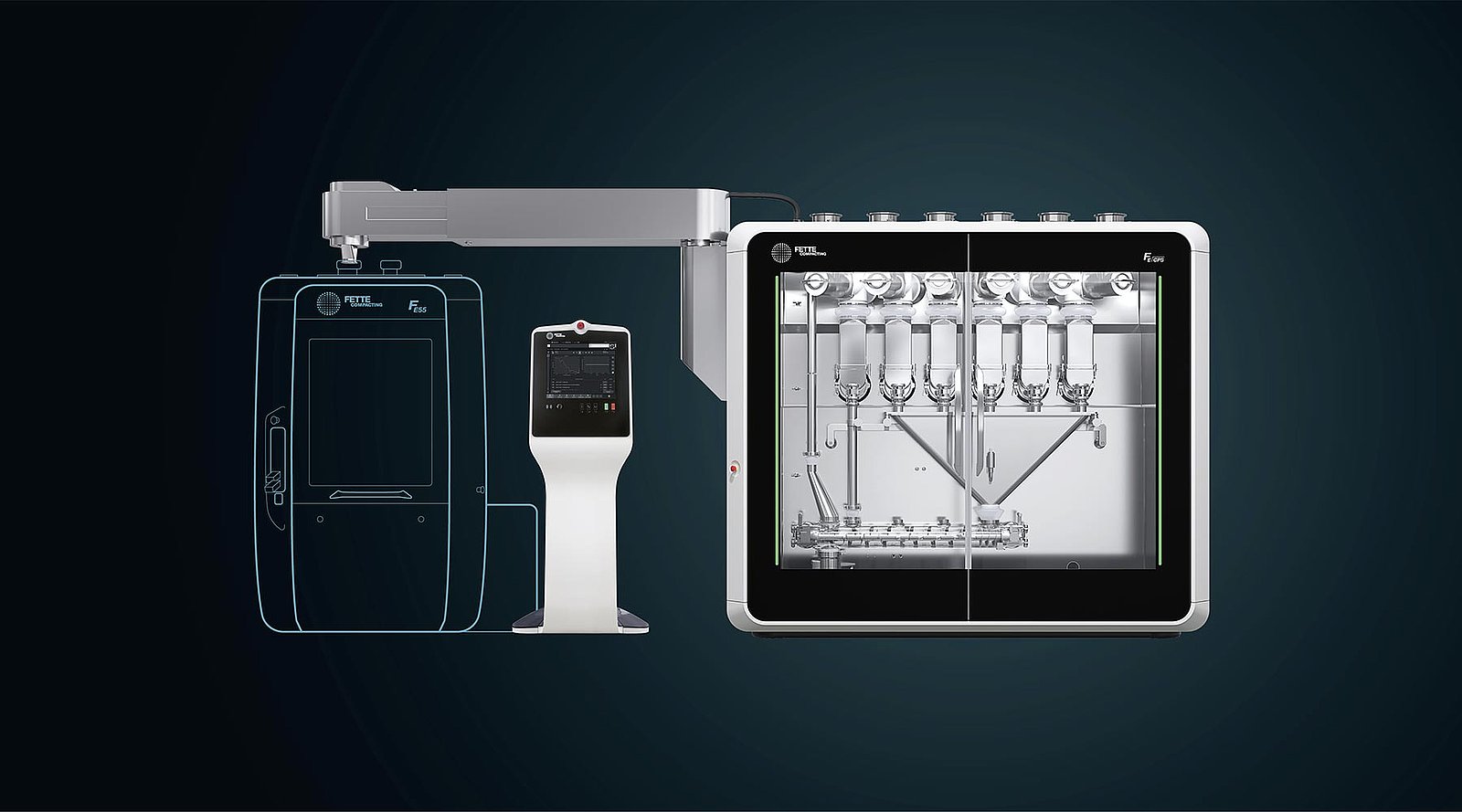

该系统由压片机、操作单元(人机界面-HMI)和连续配料-混合-输送系统FE CPS(示例性安排)组成。

直接压缩技术

的革命

一项新技术--向前迈进了一大步。FE CPS已经准备好使连续直接压缩成为您长期以来所要求的紧凑、高效和简单。在这里你可以了解到FE CPS是如何改变更先进的固体生产方式的。 固体物质生产的游戏规则。

压片

在现有的压片生产设施中,仅在一层楼内即可完成设置。

模块

安装灵活,有独立的配料/混合装置。

通用

用于处理众多配方的通用工艺设计。

安全

具有独立工艺区和技术区的防尘单元。

快捷

降低了复杂性,实现了极快的清洁和转换。

简单

TRI.EASY简化了操作:一个终端就能完成所有的程序。

受控

完全集成的在线过程分析技术(ePAT)。

FE CPS

重塑持续制造

特点

- 垂直或水平设置的安装

- 灵活的配料-混合-输送模块

- 分离出一个工艺区和一个技术区

- 快速和简单的产品转换能力

- 完全嵌入的过程分析技术

- TRI.EASY设计

吞吐能力

10 ~ 200kg/h(取决于配方和片剂)

尺寸和重量

| 高度 | 宽度 | 深度 | 重量 |

| 2,300mm | 2,650mm | 925mm | approx. 5,000- 5,500 kg |

想了解更多关于FE CPS的信息吗?

如果您需要更多的信息和详细的建议,请不要犹豫,与我们联系。我们期待着收到您的电话或电子邮件。

全球销售

菲特(中国)制药科技有限公司

江宁区盛通路9号

南京市,江苏省

中国