Grupo Ferrer Internacional is dedicated to the development of transformative medicines for serious diseases. “Transformative” means that the drugs not only alleviate symptoms, but also fundamentally change the course of the disease. The aim is to sustainably improve patients’ quality of life. In order to fulfill this mission under the highest quality standards, the pharmaceutical company has opted for a third FE55 tablet press.

Ferrer, which has its headquarters in Barcelona, is known worldwide for its solutions for the treatment of life-threatening diseases. With a focus on vascular diseases, lung diseases and rare neurological disorders, the pharmaceutical manufacturer is setting new standards in healthcare in more than 100 countries. “Our 1,800-strong team is driven by a common goal: to significantly improve the lives of sick people,” emphasizes Lambert Guri, Senior Engineering & Facilities Manager at Ferrer.

The product range includes numerous medications in tablet form. The company places high demands on their production: maximum production capacity of the tablet presses and smooth processes thanks to compatible machines. Ferrer also needs the right technology for two-layer tablets in order to be able to combine different active ingredients. “For us, it is crucial that production is not only efficient, but also flexible and absolutely reliable in terms of quality,” Guri continues.

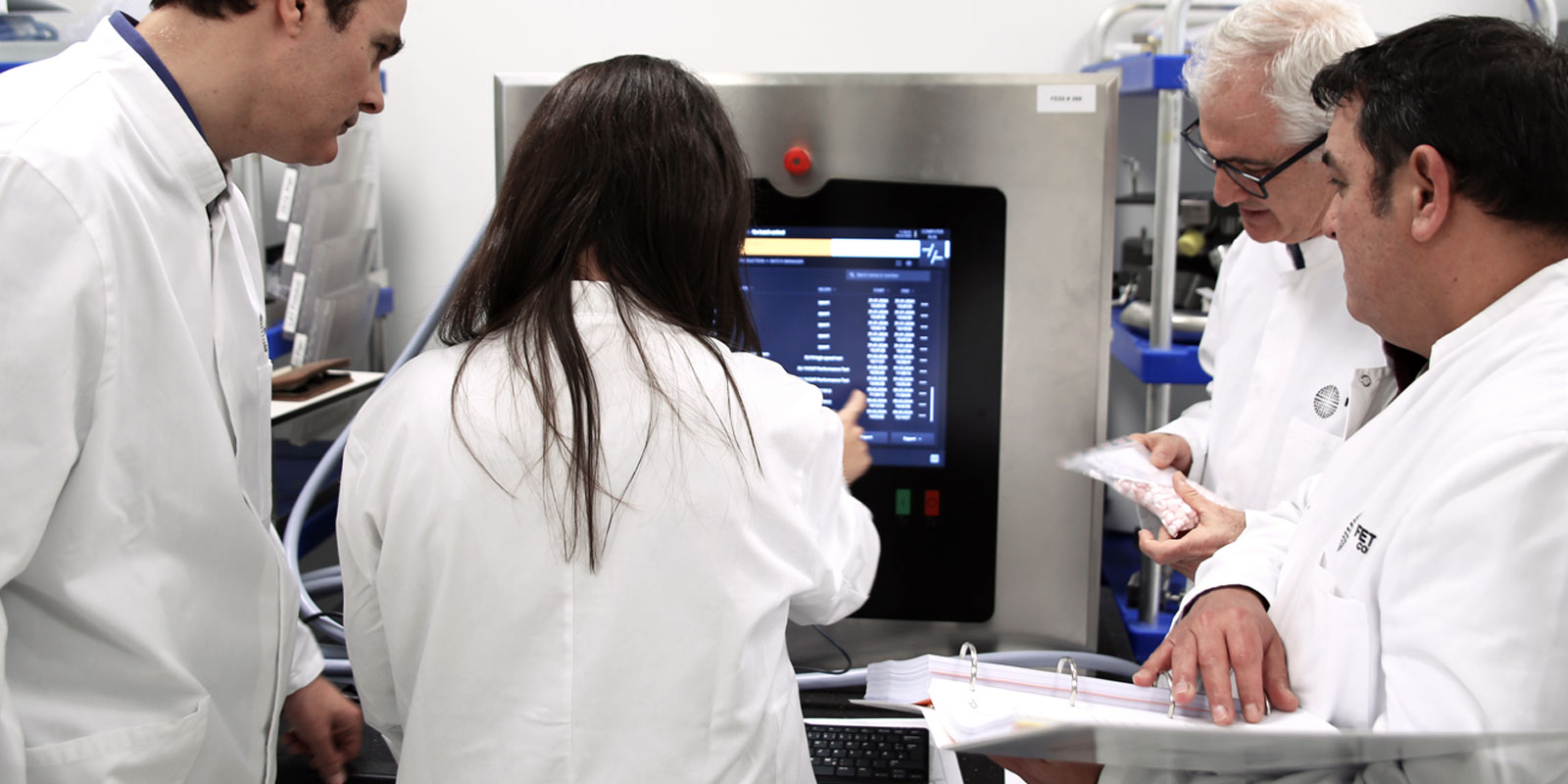

Fine tuning of the system parameters: in the production of transformative medicines, every process detail is crucial.

30 years on a joint mission

The long-standing collaboration with Fette Compacting, which began over 30 years ago, was a decisive factor in the selection of the new FE55 tablet press. Ferrer already owns two high-performance rotary presses of this type. The company has now opted for a third machine to increase production capacity and ensure continuity with maximum system harmony.

Why the FE55? The FE Series medium tablet press is one of the most powerful and versatile machines of its kind. It makes it possible to produce more than 90 percent of all common tablets, including the two-layer tablets developed by Ferrer. Maximum efficiency is ensured by the ratio of the number of punches to the footprint – up to 87 punches per to 1.6 square meters – and a special pattern for two-layer tablets. The equipment with three compressing stations instead of two results in longer compression holding times at lower compression, which leads to gentler processing of valuable pharmaceutical materials. This configuration also allows precise control of the compression force and improves the compaction of difficult-to-compress formulations. The result is denser and more uniform tablets of the highest quality.

In addition, the FE55 is designed to be easy to operate and clean. The TRI.EASY design from Fette Compacting ensures that the machine is user-friendly in terms of operation, maintenance and changeover. It offers 360-degree access and tool-free intervention during product changeovers. An intuitively controllable Human Machine Interface (HMI) provides operators with the necessary overview to easily monitor and adjust all parameters.

Future-proof positioning

With the integration of the third FE55, Ferrer expects a significant increase in its production output. The positive experience with the machines in use means that the company has a high level of confidence in the new tablet press. This confidence has been further strengthened by successful test runs and the Factory Acceptance Test (FAT) at the Customer Development Center in Schwarzenbek.

This successful cooperation is also characterized by intensive services. Fette Compacting’s technicians in Spain have extensive knowhow and ensure smooth maintenance of the machines. Following installation of the new FE55 in Barcelona, further validation steps are pending in order to optimally integrate the machine into the production environment and guarantee the highest product quality. “With the third FE55 tablet press and the proven collaboration with Fette Compacting, we believe we are ideally equipped to continue fulfilling our health mission in the future,” summarizes Lambert Guri from Ferrer.